Production engineering and manufacturing support

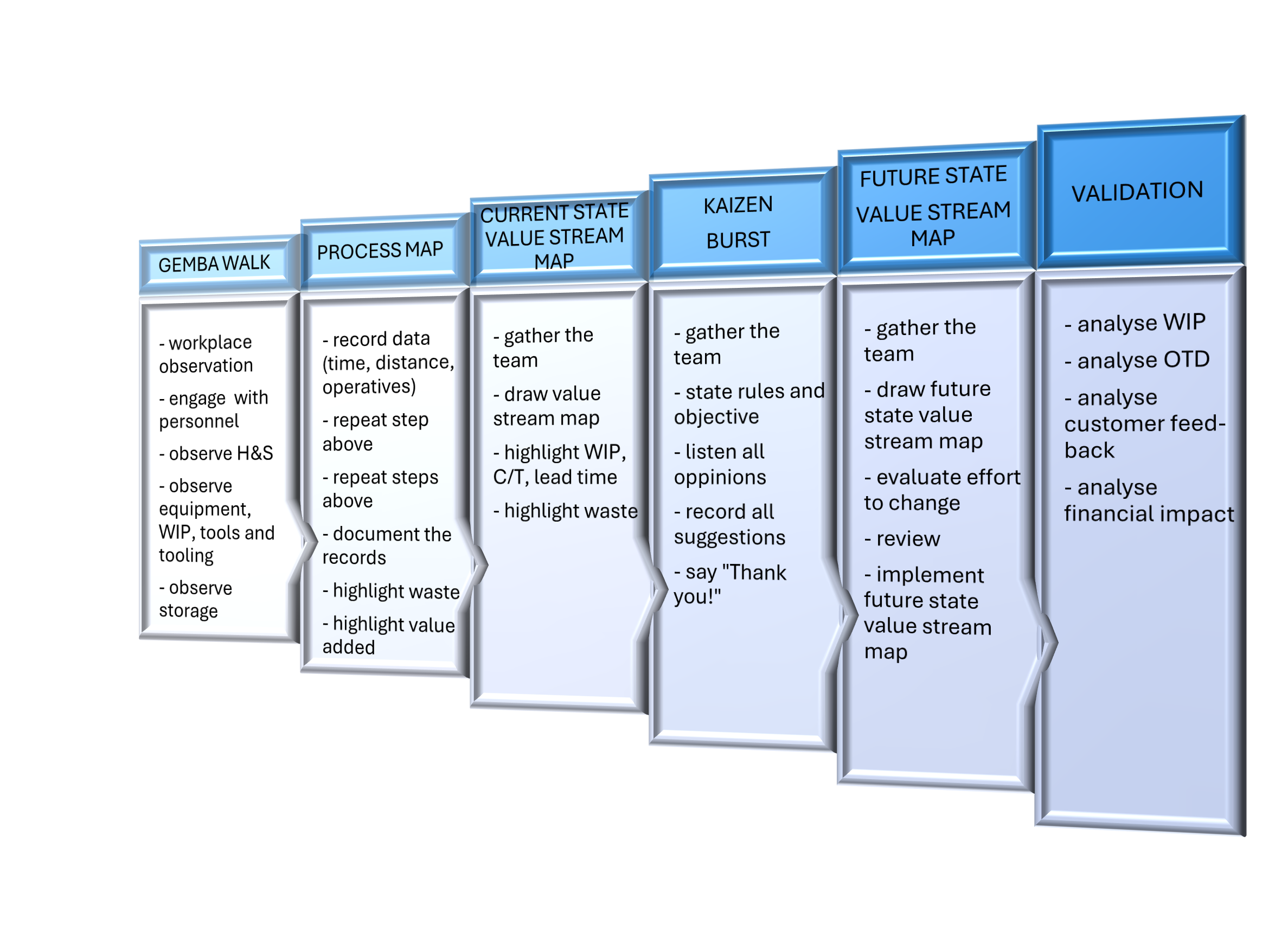

Preparation of clear work instructions and process flows is a task requiring in-depth knowledge of manufacturing processes, ability to spot process wastes and safety risks occurring in the real world of manufacturing shops. Ensuring the smooth run of the production process requires permanent review the components of the cycle time: value-added time, non-value-added time (wasted time) and required non-value time.

We are offering to our customers process mapping services by direct observation, data recording and synthesis, and the unique opportunity to gain another perspective on the production processes and a coherent alternative for process waste removal and, consequently, reduce costs, increase productivity and profit.

Recent accomplishments

2023, SKB PROD SYSTEMS S.R.L.

- successful definition of the fabrication process of telehandler main frames where key actions were related to process mapping, measured data collection and analyse and fabrication sequence correction along with welding jigs re-design. Followed by production ramp-up to match the TAKT TIME requirements.

2022, WORLDWIDE GAS S.R.L.

- Definition of gas filling production line, generating Standard Operating Procedures referring handling and storage solutions for filled cylinders

- Creation of the prerequisites for production kick-off considering European Regulation regarding safety of the operations (oxygen free, explosion risks) with pressurized bottles.

Our cornerstone on process improvement is teamwork and cross-functional team involvement and continuous observation of the impact of LEAN manufacturing KATA’s in operations efficiency and stakeholder satisfaction.

GEMBA walks, regular KAIZEN events to review the value streams and constant monitoring of key performance indicators are part of our daily activities.